At first glance, a dehumidifier with a built-in pump seems like an obvious improvement.

- No buckets to empty.

- No reliance on gravity drainage.

- Just continuous moisture removal, even in basements below the drain level.

But in real-world residential use—especially in U.S. basements and utility spaces—the pump is often the first component to create problems, not the feature that eliminates them.

So the real question isn’t whether pumps are convenient. It’s whether the way most pumps are designed actually makes dehumidifiers better over time.

What a Pump Actually Does in a Dehumidifier

A dehumidifier pump exists for one purpose:

to move collected condensate water against gravity when natural drainage isn’t possible.

This is essential when:

-

The unit sits below a floor drain or sewer line

-

Water must be lifted to a sink or standpipe

-

Finished basements lack accessible drainage

In these cases, a pump isn’t optional—it’s functional infrastructure.

However, adding a pump fundamentally changes how the dehumidifier fails, ages, and is maintained.

The Real Advantages of Dehumidifiers With Pumps

1. Drainage Flexibility That Gravity Can’t Provide

A pump allows water to be discharged upward or horizontally, enabling installation in spaces where gravity drainage simply does not work.

This is particularly valuable in:

-

Finished basements

-

Laundry rooms without floor drains

-

Utility rooms below grade

2. True Set-and-Forget Operation

Bucket-based dehumidifiers rely on human attention. Pumps do not.

For long-term moisture control—vacation homes, rental properties, or unattended basements—a pump eliminates the most common interruption: a full bucket that silently shuts the system down.

3. Cleaner, Safer Installations

Routing hoses upward keeps water lines off the floor, reducing trip hazards and accidental disconnections—especially important in finished or occupied spaces.

Where Built-In Pumps Fall Short (What Most People Miss)

1. Pumps Fail More Often—And the Reasons Are Structural, Not Accidental

In real-world use, condensate pumps fail more frequently than compressors or fans—not because they are poorly manufactured, but because they operate under fundamentally harsher conditions.

Compressors and fans move air. Pumps move condensate water, which is not clean water.

Condensate carries dissolved minerals (such as calcium and magnesium), dust particles, and biological debris pulled from the air. As water repeatedly flows and evaporates inside a small pump chamber, mineral deposits slowly accumulate on internal surfaces and impellers.

Over time, this buildup:

-

Narrows internal clearances

-

Increases startup resistance

-

Raises the mechanical load on the pump motor

This degradation is gradual, predictable, and unavoidable.

2. High Start–Stop Frequency Accelerates Wear

Unlike compressors, which operate in relatively long cycles, condensate pumps activate every time water reaches a trigger level.

In humid environments, this can mean:

-

Dozens of start cycles per day

-

Repeated high inrush current to a small motor

-

Accelerated electrical and mechanical fatigue

Each start places more stress on the pump than steady operation ever would.

3. Cold Environments Make Pump Stress Worse

Basements in many U.S. regions—especially the Midwest and Northeast—remain cool year-round.

Lower water temperatures increase viscosity, requiring more torque for pump startup. Small integrated pumps typically lack the robust thermal protection and torque margin built into compressors, making them more vulnerable to cold-start stress.

4. Pumps Are High-Complexity, Low-Redundancy Components

A built-in pump combines multiple failure-sensitive parts:

-

A small electric motor

-

An impeller

-

A float or level sensor

-

Check valves and seals

Failure of any single element stops drainage entirely. By contrast, a partially degraded fan or compressor often continues operating at reduced efficiency rather than complete shutdown.

Built-In Pump vs External Pump: What Professionals Prefer

Water-damage restoration professionals rarely rely on built-in pumps. Instead, they commonly pair:

-

Standard dehumidifiers

-

With external condensate pumps

The reason is not performance—it’s serviceability.

External pumps:

-

Are inexpensive

-

Can be replaced independently

-

Isolate failure from the main system

This comparison highlights a critical insight:

The weakness isn’t pumping—it’s non-serviceable pumping.

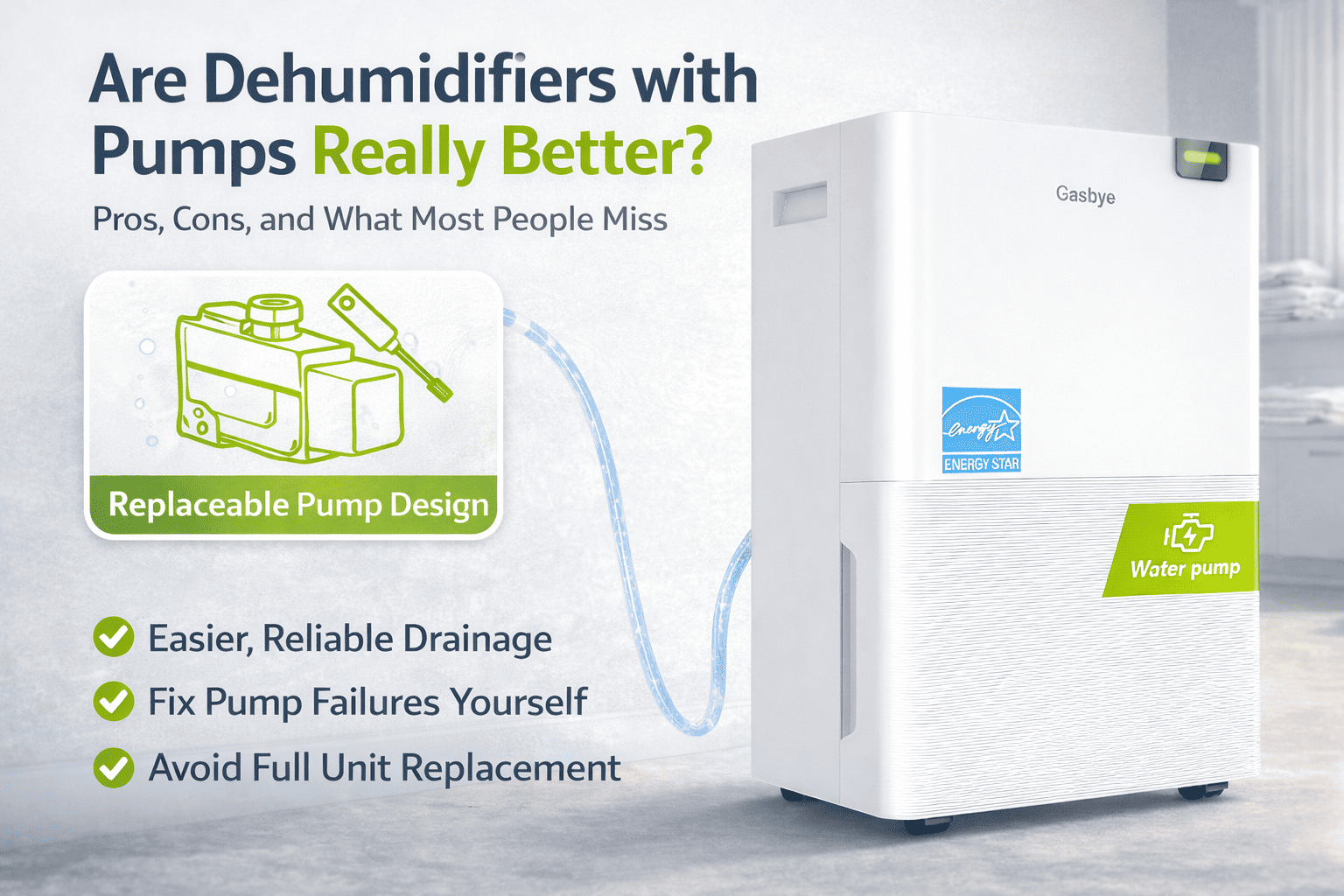

Why Replaceable Pumps Change the Equation

A replaceable pump design acknowledges an engineering reality: Pumps are wear components.

When a pump is sealed inside a dehumidifier, inevitable wear turns a minor, predictable failure into a system-level failure. The compressor, coils, and fan may remain perfectly functional, yet the entire unit becomes unusable.

A replaceable pump isolates that risk.

When mineral buildup or mechanical wear eventually takes its toll, the repair is:

-

Localized

-

Affordable

-

Fast

This shifts ownership from “replace the unit when the pump fails” to “maintain the system over time.” That difference rarely appears in marketing copy—but it defines long-term reliability.

Who Actually Benefits From a Dehumidifier With a Pump

A pump-equipped unit makes sense if:

-

The space sits below the available drainage

-

Continuous, unattended operation matters

-

Long-term reliability is a priority

-

Drainage flexibility outweighs mechanical simplicity

In these cases, a well-designed pump system adds genuine value.

Who Does Not Need a Pump

You likely don’t need a pump if:

-

A floor drain is available

-

Gravity drainage is easy to implement

-

The unit runs seasonally

-

Simplicity matters more than automation

Adding a pump where it isn’t required increases complexity without solving a real problem.

Frequently Asked Questions

Why do dehumidifier pumps fail more often than compressors or fans?

Because pumps handle condensate water, not air. Condensate contains dissolved minerals, dust, and biological debris that gradually build up inside the pump. Combined with frequent start–stop cycles and cold basement temperatures, this creates higher mechanical and electrical stress than most other dehumidifier components experience.

Are dehumidifiers with built-in pumps actually worth it?

They are worth it only when gravity drainage isn’t possible and continuous operation matters. In spaces with floor drains or short drainage paths, a pump adds complexity without providing a meaningful benefit.

What happens when a built-in dehumidifier pump fails?

In many designs, pump failure stops drainage completely. Because the pump is often sealed inside the unit, repair can be difficult or uneconomical—even if the rest of the dehumidifier is still functional.

Is an external condensate pump more reliable than a built-in pump?

Often, yes. External pumps are easier to replace, isolate failures from the dehumidifier itself, and are commonly preferred in professional moisture-control setups for this reason.

Does a replaceable pump really make a difference?

Yes. A replaceable pump turns an inevitable wear-related failure into a manageable maintenance event, rather than a full unit replacement. This significantly improves long-term reliability and ownership cost.

Final Takeaway

Dehumidifiers with pumps aren’t automatically better.

They become better only when pump failure is treated as a manageable event, not a catastrophic one. The real upgrade isn’t adding a pump—it’s designing for the reality that pumps wear out.

For homeowners planning long-term moisture control, that distinction matters far more than most spec sheets suggest.

Our 2026 new DryPrime 35-WP takes a different approach. By making the pump replaceable, it prevents a predictable wear issue from turning into a full system failure—extending the usable life of the unit instead of discarding it prematurely.

It’s a design choice that prioritizes long-term ownership over short-term convenience.

Share:

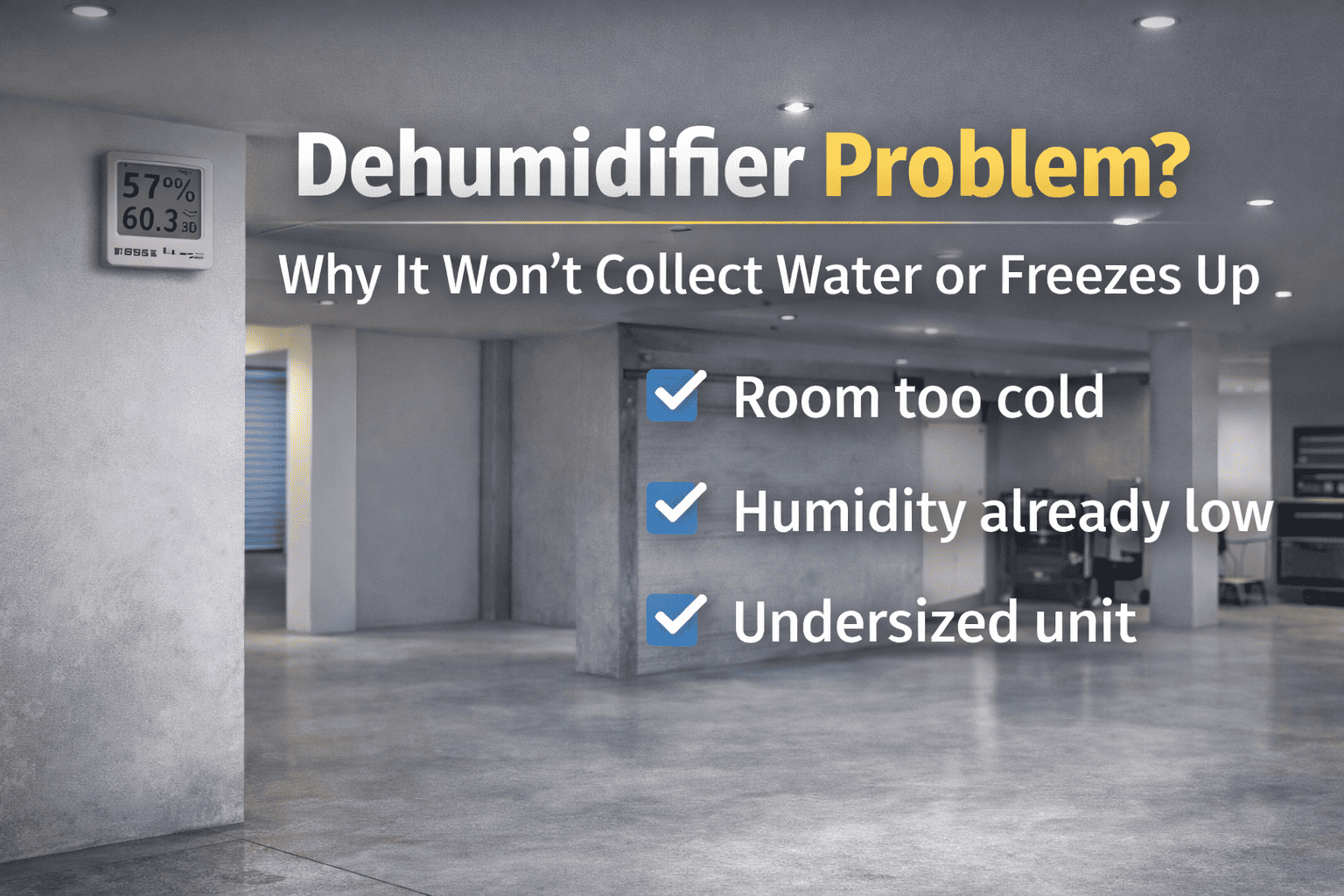

Dehumidifier Not Collecting Water or Freezing Up? Causes Explained